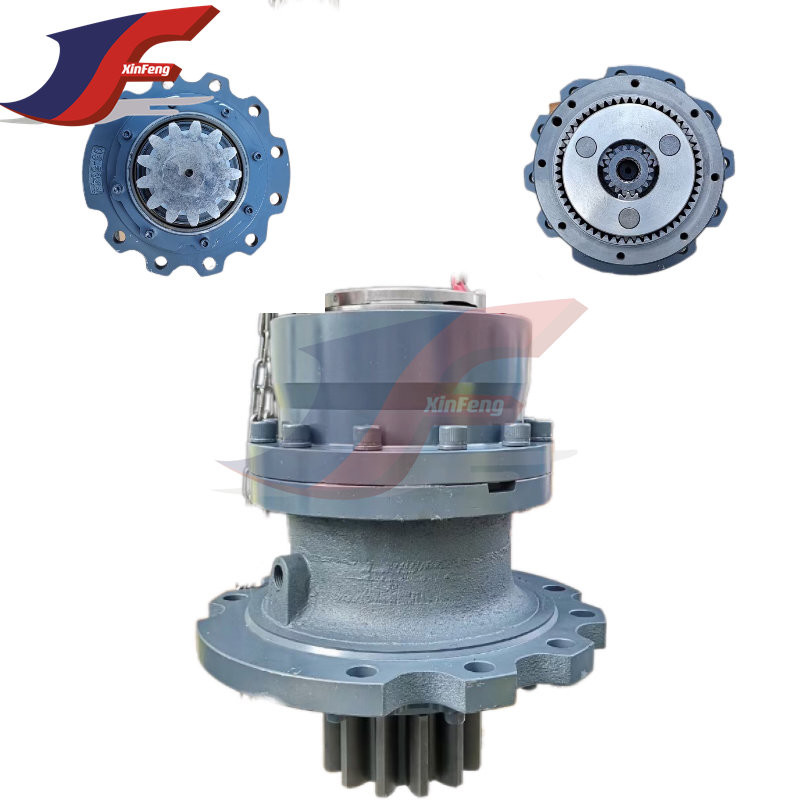

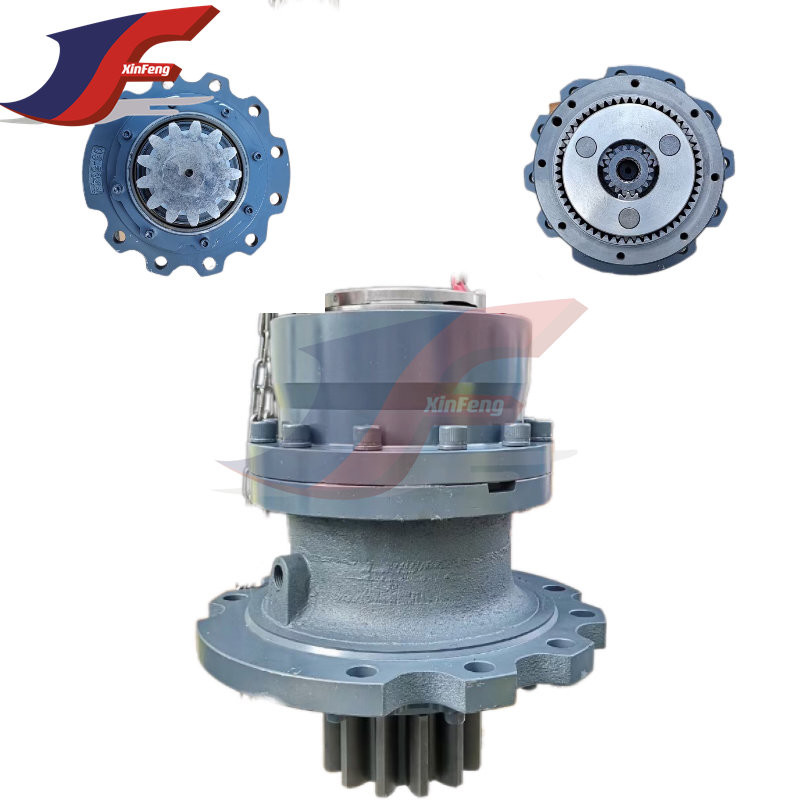

Excavator Parts EX120-2 EX120-3 Swing Gearbox 9111265 9097684 For

Hitachi

Product Descriptio

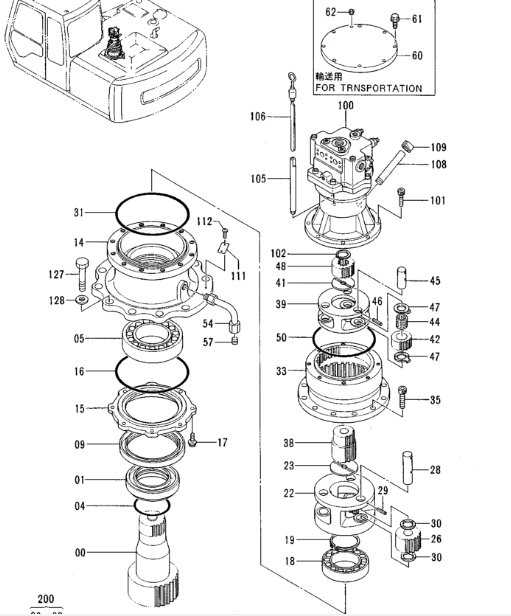

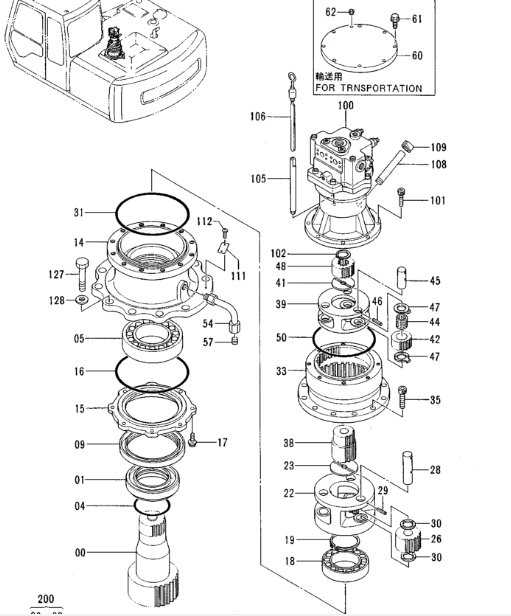

| Pos. | Part No | Qty | Parts name | Comments |

| 0 | 2028036 | [1] | SHAFT;PROP. | |

| 1 | 4244693 | [1] | SLEEVE | |

| 4 | A811100 | [1] | O-RING | |

| 5 | 4248609 | [1] | BRG.;SPH.ROL. | |

| 9 | 4244691 | [1] | SEAL;OIL | |

| 14 | 1014526 | [1] | HOUSING | T 1017261 |

| 14 | 1014526 | [1] | HOUSING | 3058620 |

| 14 | 1017261 | [1] | HOUSING | |

| 15 | 3049949 | [1] | COVER | T 3058620 |

| 15 | 3049949 | [1] | COVER | 1017261 |

| 15 | 3058620 | [1] | COVER | |

| 16 | 4247567 | [1] | O-RING | |

| 17 | J011035 | [8] | BOLT;SEMS | |

| 18 | 969154 | [1] | BRG.;SPH.ROL. | I 4293424 |

| 18 | 4293424 | [1] | BRG.;SPH.ROL. | |

| 19 | 991350 | [1] | RING;RETAINING | |

| 22 | 2031003 | [1] | CARRIER | |

| 23 | 4258089 | [1] | PLATE;THRUST | |

| 26 | 9732811 | [3] | GEAR;PLANETARY | |

| 28 | 4244696 | [3] | PIN | |

| 29 | 4063351 | [3] | PIN;SPRING | |

| 30 | 4266255 | [6] | PLATE;THRUST | |

| 31 | 4247567 | [1] | O-RING | |

| 33 | 2028037 | [1] | GEAR;RING | |

| 35 | M341450 | [12] | BOLT;SOCKET | |

| 38 | 3046918 | [1] | GEAR;SUN | |

| 39 | 2031106 | [1] | CARRIER | |

| 41 | 4244904 | [1] | PLATE;THRUST | |

| 42 | 3046916 | [3] | GEAR;PLANETARY | |

| 44 | 4249345 | [3] | BRG.;NEEDLE | |

| 45 | 4244689 | [3] | PIN | |

| 46 | 4116307 | [3] | PIN;SPRING | |

| 47 | 4269480 | [6] | PLATE;THRUST | |

| 48 | 3046917 | [1] | GEAR;SUN | |

| 50 | 4244541 | [1] | O-RING | |

| 54 | 8050210 | [1] | PIPE | |

| 57 | 94-2012 | [1] | PLUG | |

| 60 | 8053413 | [1] | COVER | (for transportation) |

| 61 | J011050 | [8] | BOLT;SEMS | (for transportation) |

| 62 | 94-2011 | [1] | PLUG | (for transportation) |

| 100 | 4241171 | [1] | MOTOR;OIL | |

| 101 | M341028 | [8] | BOLT;SOCKET | |

| 102 | 927488 | [1] | RING;RETAINING | |

| 105 | 4264452 | [1] | PIPE | |

| 106 | 3053451 | [1] | GAUGE;LEVEL | |

| 108 | 4255227 | [1] | PIPE | |

| 109 | 4255226 | [1] | CAP | P 4298608 |

| 109 | 4298608 | [1] | CAP | |

| 111 | 3053093 | [1] | NAME-PLATE | |

| 112 | M492564 | [2] | SCREW;DRIVE | |

| 127 | J932060 | [10] | BOLT | |

| 128 | 4018545 | [10] | WASHER | |

| 200 | 9111265 | [1] | SWING DEVICE | (WITHOUT MOTOR) |

Theory

The excavator gearbox is an important part of the excavator

transmission system. Its main function is to transmit the power of

the engine to the working device of the excavator through gears to

realize operations such as excavation, loading, and steering. The

following is the basic principle of the excavator gearbox:

Gear transmission: The excavator gearbox uses gear transmission to

realize the transmission of power. A gear is a disc-shaped

mechanical part with a series of tooth-shaped protrusions on it.

The gearbox usually contains multiple gears, which transmit power

through meshing. The larger gear is called the driving gear, and

the smaller gear is called the driven gear. The driving gear is

powered by the engine and transmits power to the driven gear

through the meshing of the gears, thereby driving the working

device of the excavator.

Gear ratio: The gears in the gearbox realize the conversion of

speed and torque through different sizes of teeth. The gear ratio

in the gearbox refers to the ratio of the number of teeth of the

driving gear and the driven gear. When the number of teeth of the

driven gear is less than that of the driving gear, the transmission

ratio is greater than 1, which can achieve torque amplifiion, which

is suitable for working conditions requiring large torque output.

When the number of teeth of the driven gear is greater than that of

the driving gear, the transmission ratio is less than 1, which can

achieve speed amplifiion, which is suitable for working conditions

requiring high-speed operation.

Gearbox structure: Excavator gearboxes usually consist of multiple

gears and shafts. Gears and shafts are supported by bearings to

enable smooth rotation. In the gearbox, gears are usually

distributed on different parallel shafts, and power transmission is

achieved through synchronous meshing. The gearbox may also include

accessories such as clutches and brakes to achieve control and

protection of the transmission system.

Lubriion system: The excavator gearbox will generate greater

friction and heat during operation, so a lubriion system is

required to reduce friction, cool and protect the gearbox. The

lubriion system usually includes components such as oil pumps, oil

tanks and oil pipes to transport lubriing oil to various parts of

the gearbox to form a lubriing film to reduce gear wear and

friction.

In summary, the excavator gearbox realizes power transmission

through gear transmission and speed and torque conversion through

gear ratio. The structure is complex and requires a lubriion system

to ensure normal operation. The appliion of these principles

enables excavators to complete various work tasks efficiently and

accurately.

About Xinfeng Machinery (XF) parts:

Advantages

Warehouse Display

Packaging and Delivery

FAQ

1.How to quickly and accurately buy products what lneeded?

A:Provide the original parts number to us to check.

2.How long have you been in the excavator

A:We are engaged in excavator parts since 1998

3.lfI don't know the part number,what shouldI do?

A:Please send us size and pictures of old products.

4.What is the warranty of the products?

A:The warranty is 6/12 Months based on the specific product.

5.How long is your delivery time?

A:The normal delivery time is 3-5 days for stock sproductsafter

getting payment. lf not in stock, we will inform you thetime

requlred.

6.Which shipping term you can supply?

A:By sea,air or by express ( DHL,Fedex,TNT,UPSEMS)

7.What is your MOQ?

A:Small order and sample order are acceptable

8.Do you have any After-Sales service?

A:Yes!Our