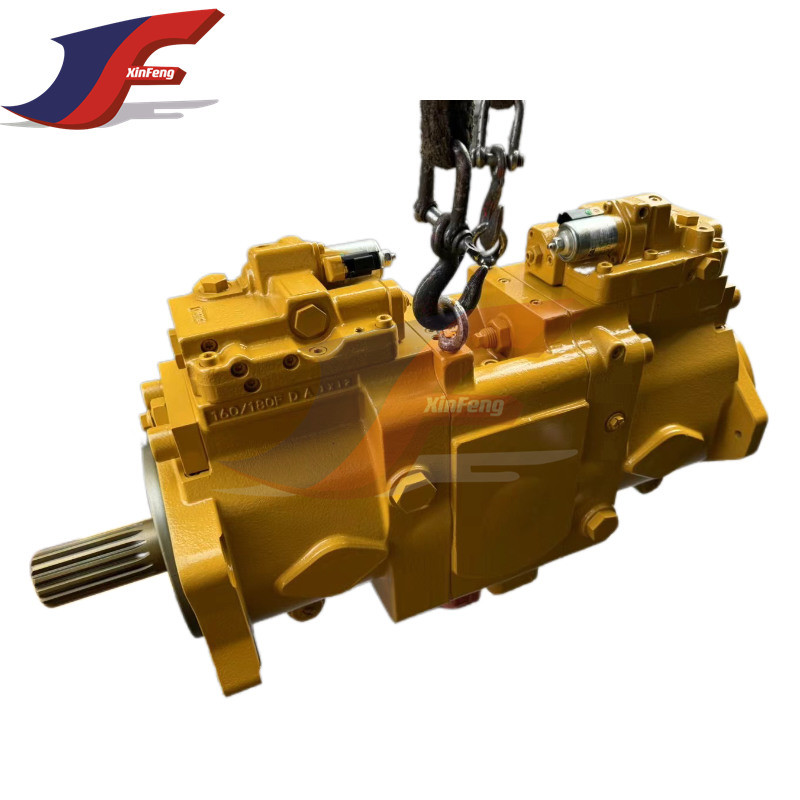

About Xinfeng Machinery (XF) parts:

Xinfeng Machinery Parts Company was established in 1998. It is a

professional team composed of high-quality technical personnel

integrating production, maintenance, sales, and service. It is

committed to providing customers with high-quality and efficient

services. It is headquartered in Guangzhou, China.

We have been engaged in the excavator industry for 25 years. We

sell original used parts, rebuilt parts,original new parts, and OEM

new parts for many types.We can provide many types for you to

choose from. We can provide a quality-trusted full range of

hydraulic pumps, travel motors, final drives, main control valves,

swing motors, and engines for KOMATSU, , HITACHI, JOHN DEERE,

VOLVO, CASE JCB, KOBELCO, NEW HOLLAND, SUMITOMO, KATO, BOB, DOOSAN,

and HYUNDAI.

We provide a customer satisfaction guarantee on all our products.

We have invested in providing only the highest-quality replacement

parts to our customers. Develop a more broad business space

together based on long-term, friendly, mutually beneficial, and

win-win business relations.